How Renew Sodium Silicate Works

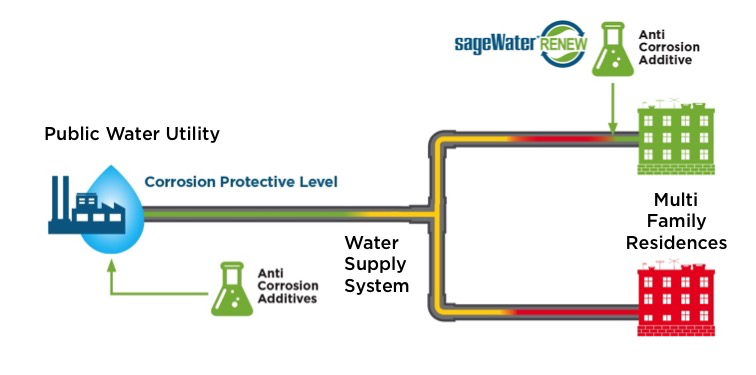

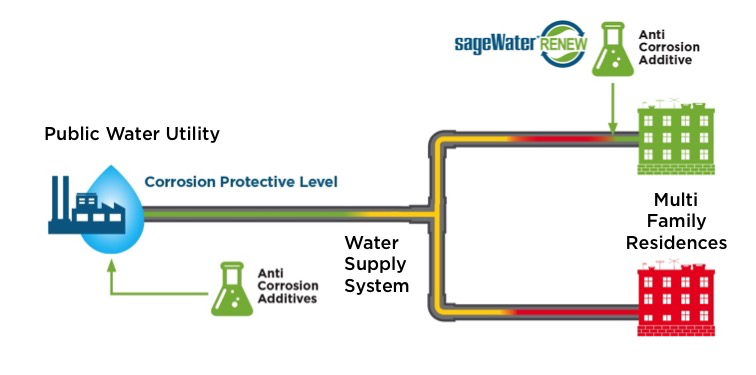

Municipal water authorities add corrosion inhibitors to the water supply system to prevent pipe corrosion inside their miles of pipes. They spend over $36 billion on these anti-corrosive additives, yet the protection does not extend all the way to buildings and homes. Renew implements the same anti-corrosive treatment for multifamily buildings, including apartments and condos, to provide pipe protection where the water authority left off. The treatment uses a sodium silicate additive at far lower levels than is found in some popular commercial bottled waters and is safe and effective.

Our additive forms a thin protective layer on the inside of pipes that prevents further pipe corrosion and stops pinhole leaks from forming. Over time, the layer does not increase in size, can repair itself if damaged, and prevents further leaks and pipe corrosion as long as the sodium silicate additive feed is continued.

The Science & Technology Behind Renew

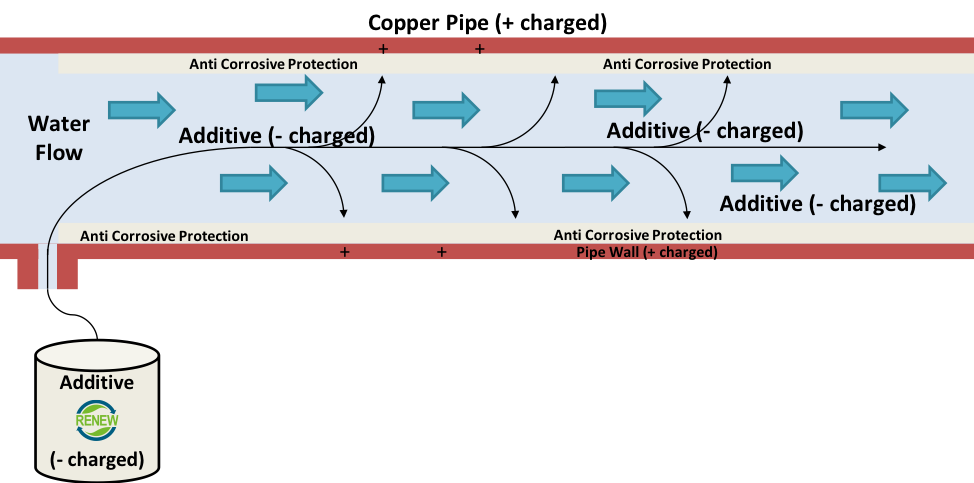

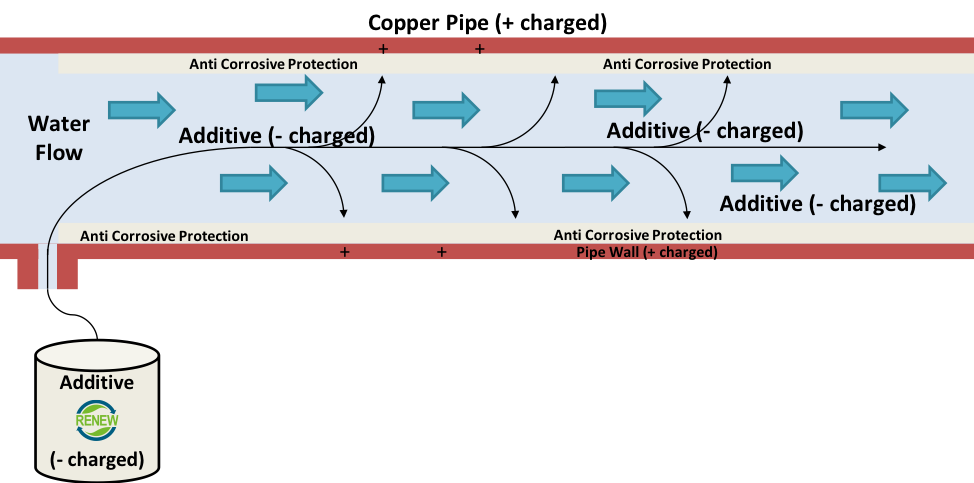

The anti-corrosive is dripped into the plumbing system in proportion to water flow. The additive dissolves in the water and has a slightly negative charge, which is attracted to the inside of the positively charged pipes. A microscopic insulation layer forms inside the pipe and protects from corrosive elements and leaching of lead and other materials. The layer protects all metal pipes downstream from the injection feed including supply lines, risers and small diameter pipes within units.

The anti-corrosive is dripped into the plumbing system in proportion to water flow. The additive dissolves in the water and has a slightly negative charge, which is attracted to the inside of the positively charged pipes. A microscopic insulation layer forms inside the pipe and protects from corrosive elements and leaching of lead and other materials. The layer protects all metal pipes downstream from the injection feed including supply lines, risers and small diameter pipes within units.

The Renew team provides a turnkey service so that property staff is freed up, not burdened, by the treatment. Renew visits the installation periodically to check equipment performance, verify the formation of the protective layer, test water chemistry, adjust treatment protocols and interact with the property maintenance team to discuss any plumbing issues on the system being treated. Data is received wirelessly 24/7. Tracking the performance of the equipment, additive usage, and exception notifications are monitored when data is outside of expected parameters.

The anti-corrosive is dripped into the plumbing system in proportion to water flow. The additive dissolves in the water and has a slightly negative charge, which is attracted to the inside of the positively charged pipes. A microscopic insulation layer forms inside the pipe and protects from corrosive elements and leaching of lead and other materials. The layer protects all metal pipes downstream from the injection feed including supply lines, risers and small diameter pipes within units.

The anti-corrosive is dripped into the plumbing system in proportion to water flow. The additive dissolves in the water and has a slightly negative charge, which is attracted to the inside of the positively charged pipes. A microscopic insulation layer forms inside the pipe and protects from corrosive elements and leaching of lead and other materials. The layer protects all metal pipes downstream from the injection feed including supply lines, risers and small diameter pipes within units.